Gas charaterization and xperimental campaigns with a mobile gas cleaning unit

In the frame of the project producer gas qualities of different gasification technologies have been evaluated, considering parameters that are relevant for the Bio-CCHP-Concept. The measurements were carried out by BEST in cooperation with all partners, employing online and offline gas analytical methods. Most significant differences were detected between air-blown and steam-blown gasifiers in water content (7 to 55 vol%, u.s.c.), methane and C2 to C6-compounds (2 to 12 vol%, u.s.c.) and tar (from below 80 mg/m³ up to 10.000 mg/m³, u.s.c.) which can lead to carbon deposition in SOFCs. At air-blow gasifiers with low amounts of hydrocarbons and simultaneous low water content, additional steam had to be added to avoid carbon deposition in the cells (compare results IEN-SOFC-experiments).

Four experimental campaigns regarding the investigation of the desulphurisation processes under real gas conditions were performed by BEST in cooperation with SynCraft, Hargassner, TU Graz and IEN. The operation temperature for desulphurisation was defined at 350°C, to ensure H2S-concentrations below 0,1 mg/m³ usc (detection limit) in the cleaned gas. The main goal of these first tests has been the monitoring of defined producer gas components before and after the gas cleaning process.

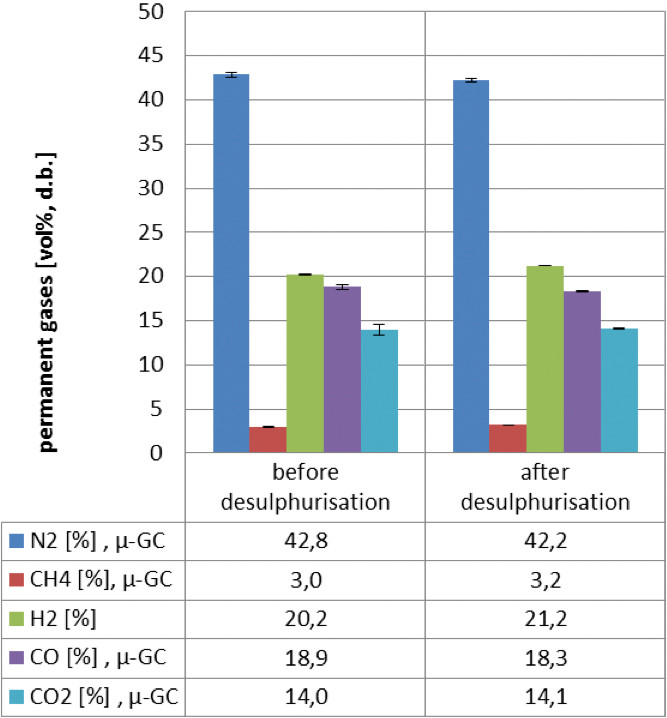

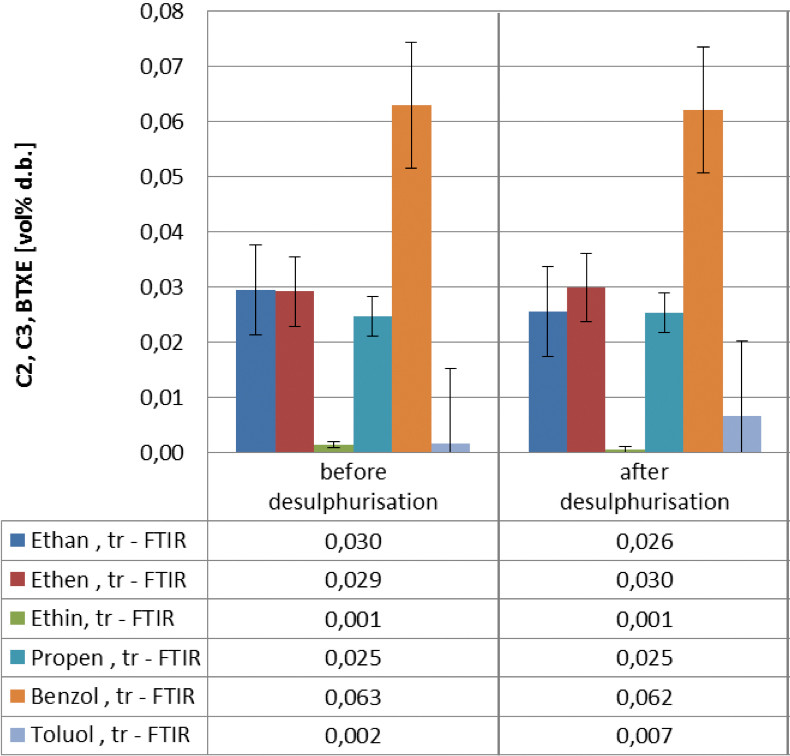

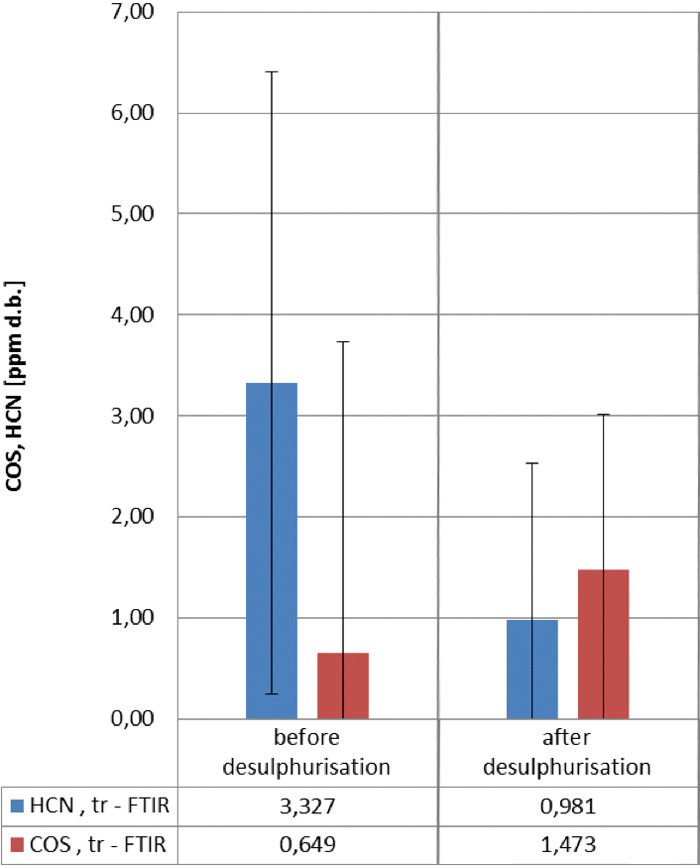

Selected results: Results of real gas experiments show that for all so far evaluated compounds except H2S no significant increase or decrease over the desulphurisation process has been observed. For COS and HCN the fluctuation of concentration is relatively high relating to the measurement value, hence, a reliable conclusion cannot be drawn.

Exemplary shown here are the results of the staged floating bed gasification thechnology of SynCraft. H2S concentrations in the raw producer gas of all test runs at both sites were between 15 and 30 mg/m³ usc., whereas clean gas concentrations had been below detection limit of 0,1 mg/m³ usc.