News

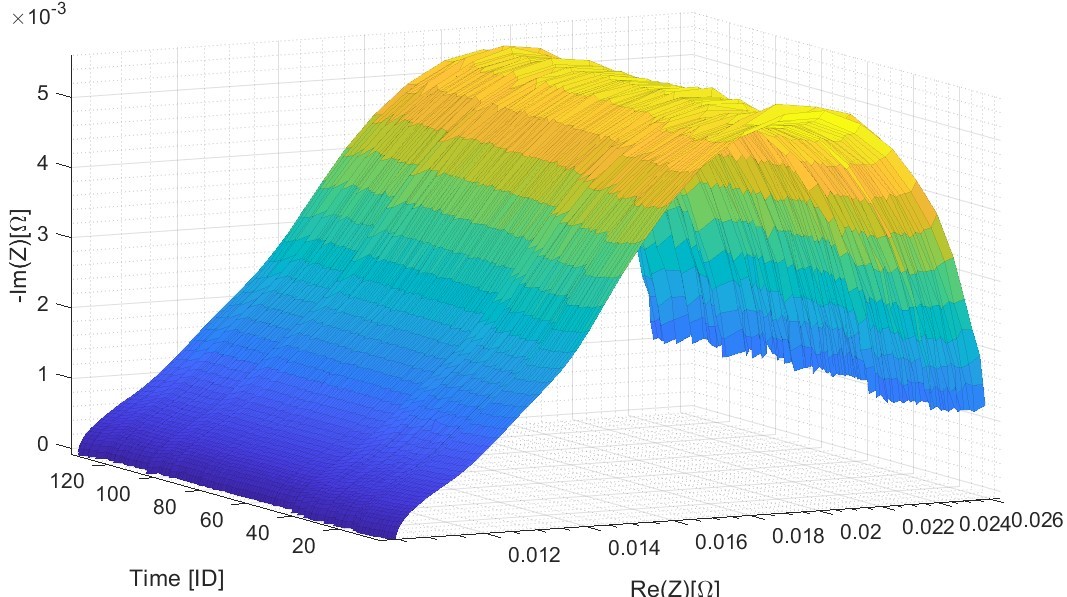

The influence of main gas components of producer gas derived from biomass gasification as well as operating temperature on the electrochemical and thermal characteristics of an industrially sized, electrolyte supported SOFC with Ni/GDC anode has been extensively investigated using electrochemical impedance spectroscopy, polarisation curves, gas analysis as well as temperature measurements within the cell holder. Moreover, a 500h test run on a gas composition with high steam content relevant for steam-blown fluidized-bed gasifiers to investigate nickel re-oxidation effects has been successfully conducted.

The collected data will help to understand electrochemical processes within the cell and as a result to identify optimal operating points for an economic coupling of biomass gasifiers with SOFC systems.

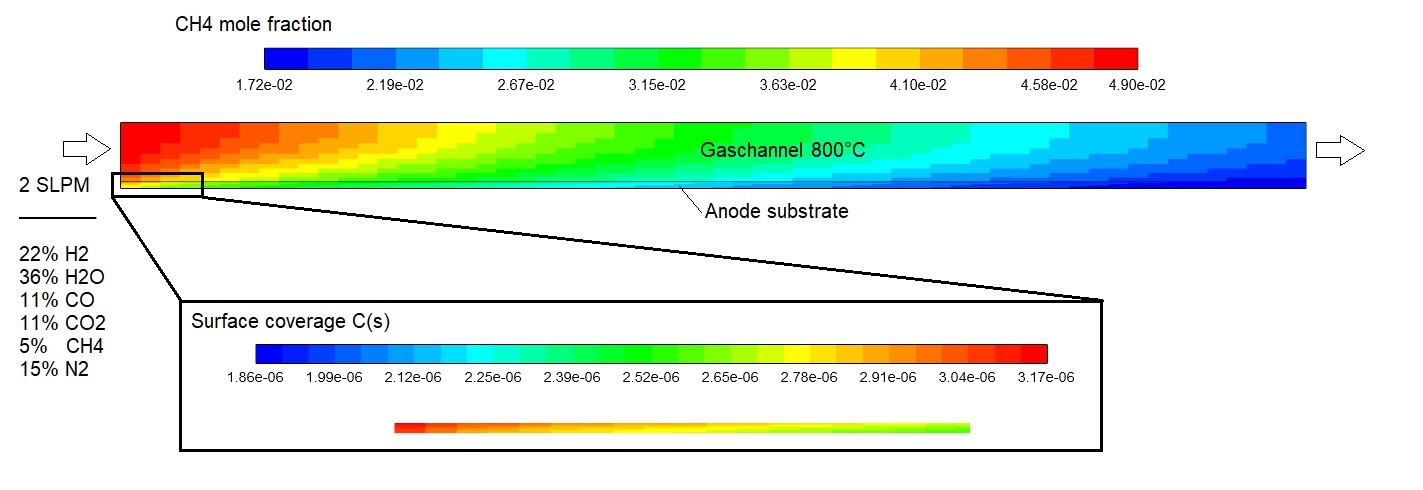

To deepen the understanding of processes within the anode substrate to conclude on cell characteristics, beforehand described measurements were supported by numerical simulations. Therefore, a 2D open circuit model with a detailed heterogeneous reaction mechanism could be created to calculate the spatial and temporal distributions of surface adsorbed species acting as possible precursors for degradation processes. To ensure time efficient simulations of future models with higher complexity (3D, additional mechanisms, solid carbon deposition formulations), studies on simulation acceleration potentials were conducted and a reduction in simulation time by 60% could be achieved.

Nearly constant impedance spectra of SOFC for 500h test run under producer gas with high steam content

Surface adsorbed carbon C(s) in a 2D SOFC model fuelled with producer gas

More News

News